The Cleanroom Environment for Hi-Tech Services

BlogPPETextilesCleanroom14.06.2022

BlogPPETextilesCleanroom14.06.2022

Cleanrooms used for manufacturing complex electronics or batteries need mitigation for potential electro-static discharge. The factors to consider in this analysis include the flooring in the cleanroom, the tools you use and the clothing you wear. All Micronclean cleanroom clothing is manufactured with a continuous carbon grid to alleviate the build up of a static charge during routine operations.

Why Use Cleanroom Clothing?

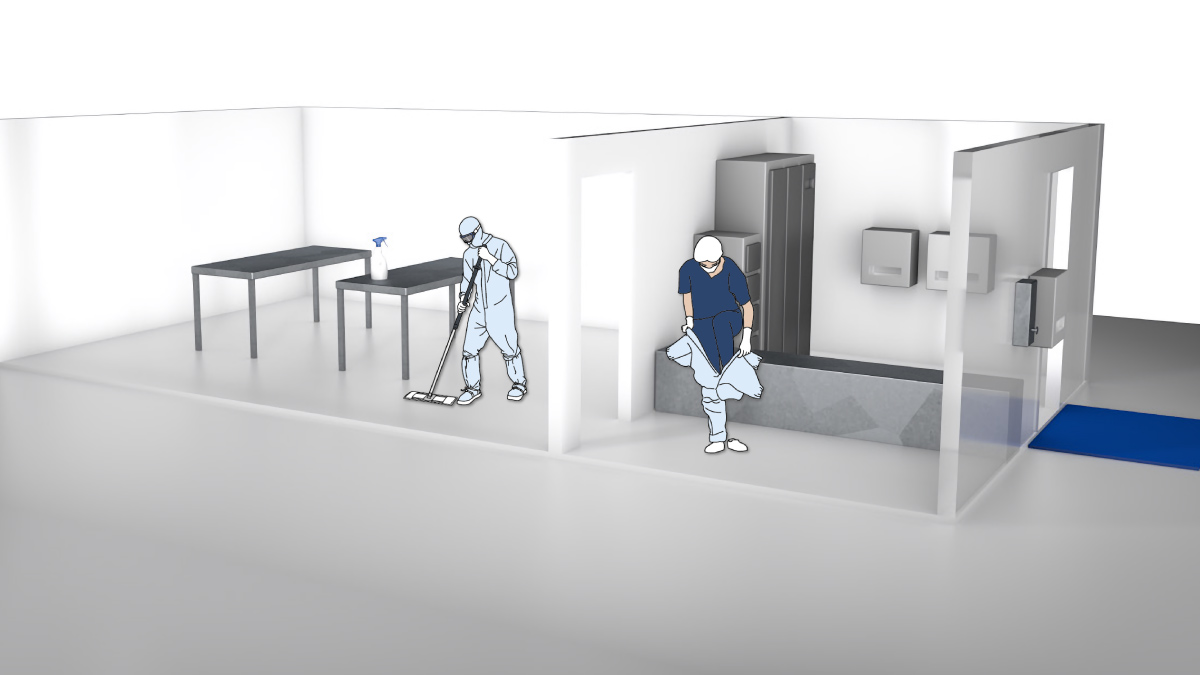

Cleanroom clothing is used as a barrier to prevent contaminants naturally shed by the wearers body contaminating the environment the product, in any cleanroom the garments used should reflect the cleanroom classification and the product specifications.

As all cleanrooms are different your garment choices and changing procedures must be validated at your site. However, Micronclean will work with you to determine your exact requirements and then generate a tailored cost effective laundered garment solution for your company which could include the provision of cleanroom lockers. We can also offer specialist advise on gowning techniques and other work practices, to help you get into production quickly. It is worth noting that anybody working in a cleanroom should be subject to rules which limit or ban the wearing of make-up, perfumes, jewellery etc. as these increase the contamination in a cleanroom.

How Should I Clean my Cleanroom?

For semi-conductors, power electronics or battery production the key requirement is to reduce and remove particulates from the air, for which we would recommend an alcohol based cleaning regime based on either IPA (Propan-2-ol) or IMS (Denatured Ethanol). Cleanrooms concerned with pharmaceutical production have an additional requirement to control bacteria and spores and this affects the choice of chemical used in these environments as they have to have a disinfection action. The key choice in any cleaning regime is in the choice of wipe where there is a trade off between higher cost wipes which shed less particles but might have reduced absorbency.

As all cleanroom are different your consumables choices and cleaning procedures must be validated at your site. However, Micronclean will work with you to determine your exact requirements and then generate a cleaning solution for your company. We can also offer specialist advise on cleaning and mopping techniques to help you get into production with less hassle.