The Laboratory’s Latest Equipment, How It Works and Why We Have It

BlogPPETextilesCleanroom16.02.2021

BlogPPETextilesCleanroom16.02.2021

As a business, many of our products use different plastic packaging, each requiring a reliable seal to ensure the contents within the packaging are protected from contamination, remain sterile, and in good condition.

We most commonly opt for heat seals to seal our packages, and to test the integrity of the seals, an immersion test was previously performed. This test entailed submerging the package in water and observing for any bubbles which may escape the packaging at the seals. The immersion test, while sufficient to provide a quick, qualitative result, was ultimately an observation test and had several variables which could influence and effect the result of the test negatively. We wanted a more quantitative, robust, and reliable test method, with equipment which would provide dependable and trustworthy results, every time. Therefore, the Micronclean Laboratory purchased The Lippke 4500 Package Test System.

The Lippke 4500 Package Test System

The Lippke 4500 Integrated Package Test System is a piece of equipment capable of measuring the seal strength and integrity of various different packages.

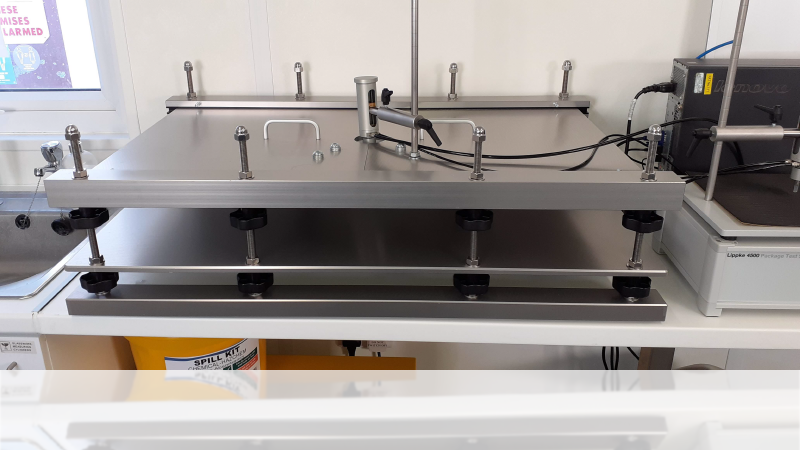

The system consists of a main console (above) and various accessory kits, in conjunction with a PC-based software application, which allows easy and quick entry, selection and management of all test parameters.

We purchased two additional kits to help us perform a range of tests on a variety of package types and sizes. The first and most commonly used accessory is the ASTM restraining plate fixture. This is used to perform restrained tests on closed packages; wherein the plates restrain the package as it is inflated to a desired pressure, to ensure the pressure affects the package seals in the right way. This fixture is used for burst and leak tests, as the restraining plates provide a basis of control as the bag is inflated, but also provide a safety aspect in that the packages aren’t inflating wildly and uncontrolled!

The second kit is the basic stand, which allows testing of fully sealed (closed), rigid and semi-rigid packages. The package is placed on the platform of the stand and is inflated with air during a burst or leak test.

How the System Works

The package test system computer programme allows various parameters of the test to be altered according to the package type and test method desired. For example, inflation rate, test pressure, leak limit etc. are just some of the settings which can be altered to perform an adequate test.

First the appropriate test is selected on the system. The parameters are then checked and altered according to the bag specification. Once both of these are selected and confirmed within the programme, the test can start. The bag being tested is then attached to the restraining plate fixture. The top two plates are separated, allowing room for the bag to be inserted and restrained between them, before the plates being closed again. A needle then penetrates the bag and is ready to inflate the package with compressed air (from a compressor connected to the system) to a set point determined within the test parameters of the system.

We primarily use the burst test (seal strength); wherein the bag is inflated to a very high pressure, causing the bag to burst and recording the burst pressure (the pressure in which the seal is broken) and the leak test (pressure lost); where the bag is inflated to a known pressure, held for a specific amount of time, then recorded for a specific test time to determine if the pressure within the bag decreases beyond the leak limit to determine if the bag has a hole or leak.

However, the system is also capable of performing numerous other seal strength and package integrity tests, including:

- Creep tests – these tests can also evaluate the strength of the seal of a package

- Creep test

- Creep2Fail test

- Combined testing:

- Combined Creep/Burst

- Combined Creep/Leak

- Combined Creep/Leak/Burst

- Bubble test – this can be used to test where a leak is placed or to check the barrier of a package

Why Do We Have This Equipment?

We aim to use The Lippke 4500 Package Test System to run quality checks on packaging; to determine if our packaging performs as expected and improves confidence in the results we report. We will also use this equipment to validate the heat sealers we use within the company to seal our packaging, both when receiving new equipment and when our current sealers are recalibrated. Ultimately this equipment will allow us to perform more accurate, reliable and consistent tests on packages, every time.

![]()

Author

Caitlin Lowes

Laboratory Technician

NOTE – All diagrams Copyright AMETEK MOCON and all details and images are correct as per the Lippke 4000/4500 User Guide 01/2018